Stormwater (SW) runoff is everyone’s responsibility and helps to keep our beautiful country clean and green. With the recent heightened focus on stormwater management throughout NZ and the need to manage stormwater in a high-velocity application — what can be done to get a decent result?

What were the issues/problems and challenges?

It is super intensive when you have an application like a launch pad and the force that it generates during a launch. Combined with trying to capture and manage the excess stormwater, coolants, fuel residue etc., you need a clever design by the team at Stiles And Hooker Consultants to keep it all onsite and to protect the surrounding environment.

In discussions with the Hynds SW team a ‘Treatment Train’ (TT) was formed not only to be functional but to keep with this client’s request to look at lessening their effect on the surroundings and for ways to reuse this runoff.

What was the solution?

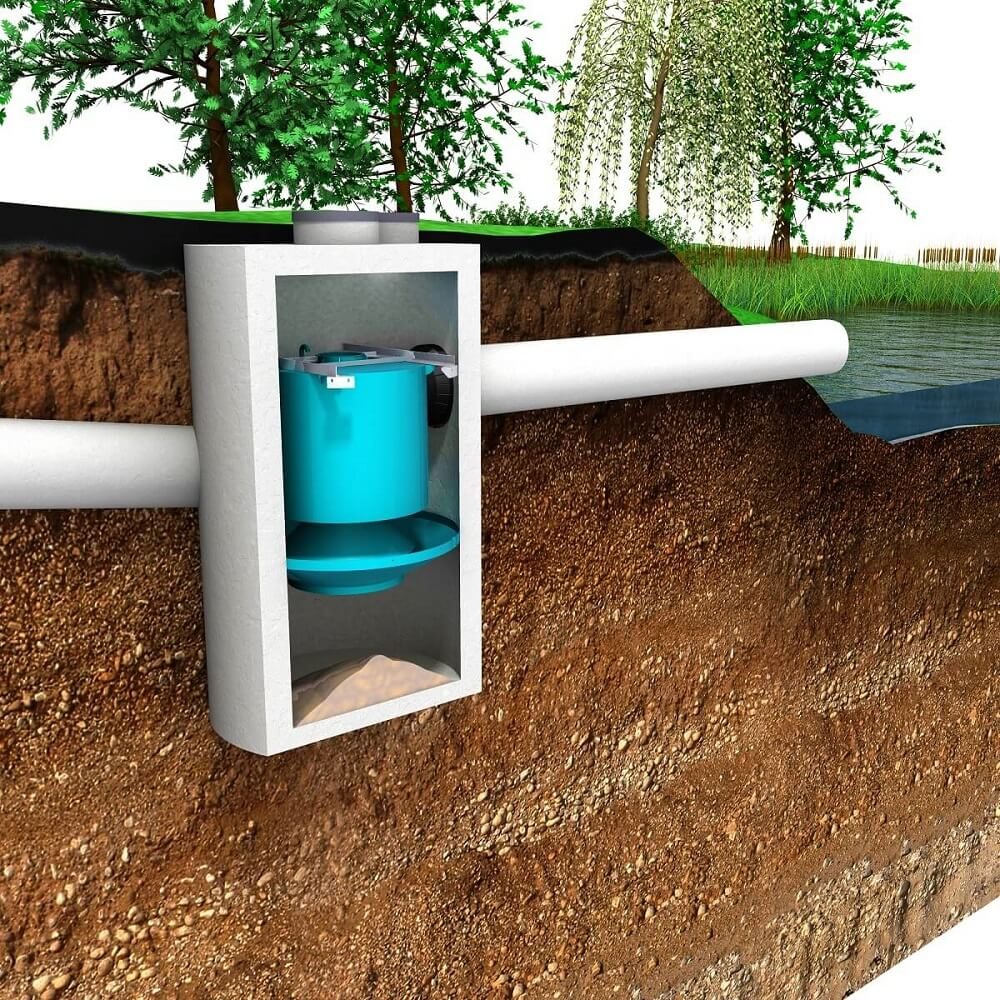

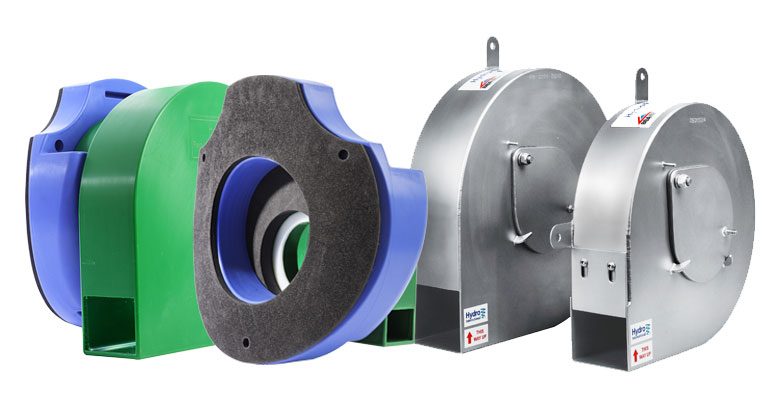

The ‘TT’ consisted of using a Hynds HydroBrake® to control the flow into the treatment train, then having a Downstream Defender® to treat sediment and free oils from blast run-off, before bringing it (SW) through an AquaFix® (this was to offer some additional ‘polishing’ treatment) while also offering the option of a shut-off valve (for a worst case situation). This then allows for the processed water to be moved into storage and for reuse.

How long did the installation take?

As the construction phaze for this project fell during the Covid-19 pandemic, speed of installation and keeping everyone safe was paramount for Mike Wilson and the team at QRS (Quality Roading and Services Ltd).

Using Hynds easy ‘Plug & Play’ solutions (from their state-of-the-art Pokeno manufacturing site); this made for a super quick install (within a few days). Their unique treatment devices housed in standard manhole structures allow contractors to easily prepare the site and install the units into place, connect and backfill.

To ensure invert-level flexibility, standard risers can be simply installed at multiple ranges of heights for easy level design and installation.

What was the desired result and benefit?

A robust and efficient SW solution that meets the high standards demanded for this pristine and delicate site, that can endure all the natural and extreme forces that will be thrown at it and also give a long-term efficient SW solution.

Why did Hynds/Hygrade get the job over the competitors?

Having the best products available with time-proven relationships with designers and contractors, plus the ability to source the right information and solutions, together with the ease to install and maintain, makes using Hynds products an easy choice to make.

What were the points of difference?

- Great products with proven results

- Great people and service, wanting to help protect our environment.

- Ease of use and service of their devices

- Dealing with a family-owned business and contractors who care about what they do